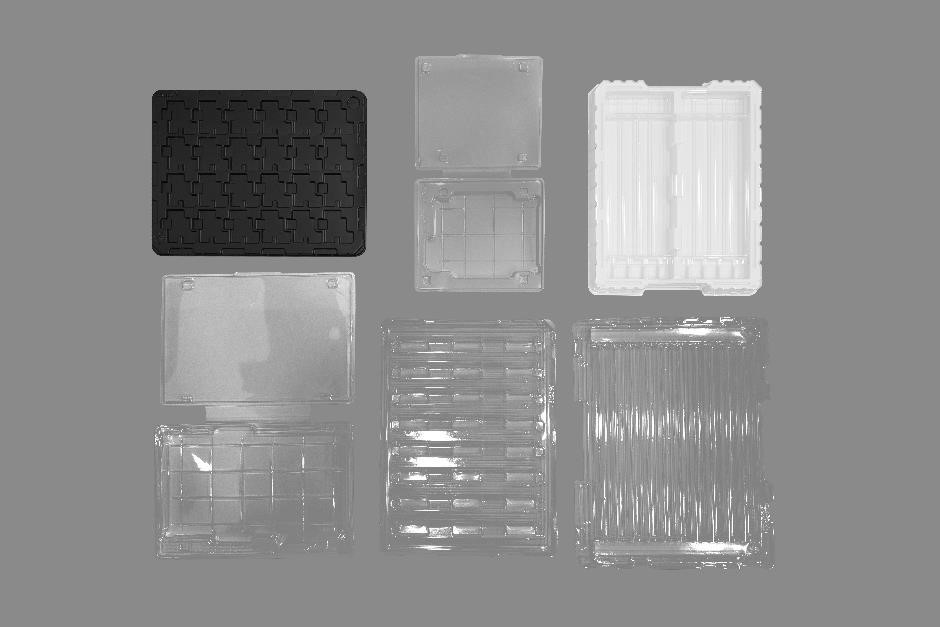

Product description:

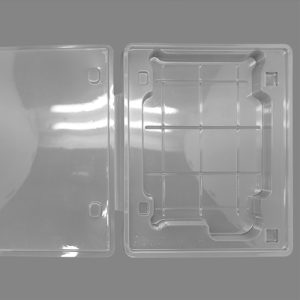

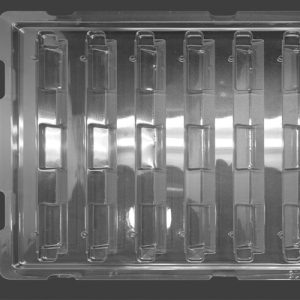

Shaped plastic vaccum trays are a diverse and important products in the packaging industry. They are typically made from plastics as PVC, PET, PP, or PS and can be formed into different shapes, sizes, and colors to suit the desire of each application.

Production process:

Step 1: Prepare material

Plastic material in rolls are prepared and loaded into the vacuum shaping machine.

Step 2: Vacuum shaping

Vacuum shaping machines use heat to soften the plastic sheet and shape it into patterned trays using vacuum pressure.

Step 3: Cut and finish the product

After being shaped, the plastic tray will be deburred around and finished with precise cut lines and a smooth surface.

Outstanding features:

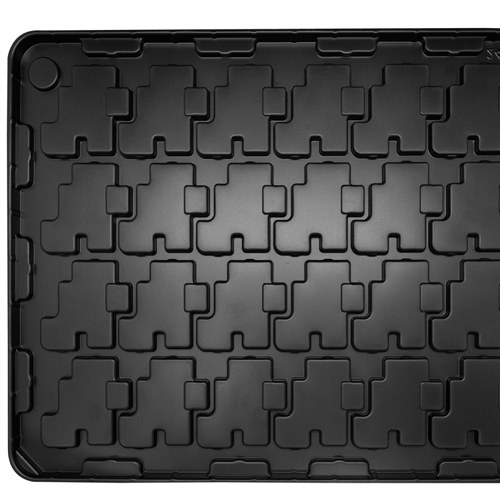

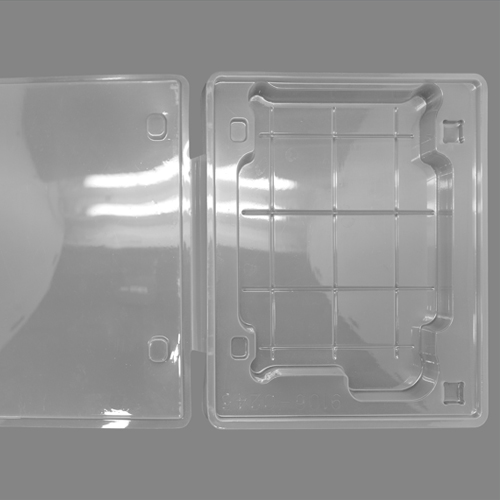

Diverse shaping capabilities: Shaped plastic vaccum trays can be formed into many different shapes and sizes to suit packaging needs.

Shiny surface: The product has a glossy surface, helping to enhance brand value.

Durable and safe: Shaped vaccum plastic provides the strength and rigidity needed to protect the product inside.

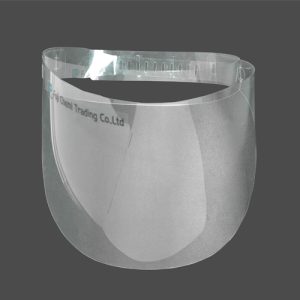

Rich colors: Black, white, yellow, red, green, transparent…

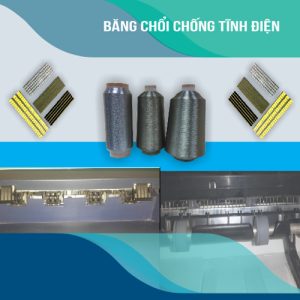

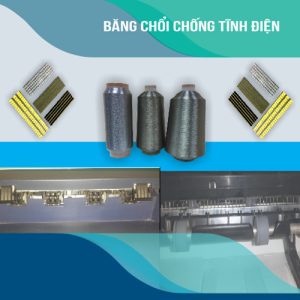

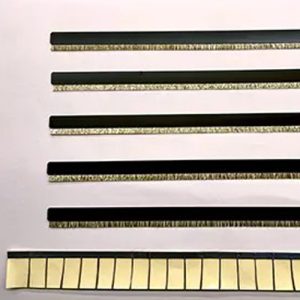

Depending on usage requirements, tray products have regular types, antistatic and conductive types…

Application:

Shaped plastic vaccum trays are widely used in many industries, including food, healthcare, electronics, and consumer products. They are often used to package and protect products, and help promote brands through diverse designs and high quality.

Producing shaped vaccum plastic trays is a complex technical process, but brings great benefits to many industries.

SSK Company has more than 10 years of experience in manufacturing shaped vacuum trays, used by many customers to package electronic parts, machine parts… We can produce trays based on your drawings, sample tray or part needs to design the tray based on the conditions that the customer desires.

Reviews

There are no reviews yet.