We provide TOUGHTRACE sanitary plastic pellets, a completely new high-quality sanitary plastic pellet, developed by NIPPON A&L INC Japan, for injection molding machines and plastic extruders. Capable of removing any type of plastic, regardless of its properties, TOUGHTRACE has an extremely low residue inside the cylinder, allowing it to be replaced with a wide range of materials, from transparent to colored, within much shorter time than conventional products.

TOUGHTRACE screw cleaning resin is a material specifically designed to clean and maintain screws during the operation of plastic injection molding machines.

TOUGHTRACE Outstanding Features:

– Cleaning effect: plastic pellets are designed with powerful cleaning additives, helping to remove dirt, residue, and grease build-up on screw surfaces.

– Material quality: Manufactured from high-quality plastic materials, ensuring quality, increasing longevity and safety for the operation of plastic injection molding machines.

– Versatile Use: The product can be used for many types of plastic injection molding machines and screws of different sizes.

Easy to use, can be used with almost any plastic, has low residue levels, is non-sticky and can be easily replaced with any plastic material during molding or extrusion. TOUGHTRACE comes in beads shape and is easy to use. Using saving and taking less time, TOUGHTRACE cleaning resin support optimize the cleaning process, minimize machine downtime and increase productivity. TOUGHTRACE is non-corrosive and will not damage cylinder liners. Minimize industrial waste, be environmentally friendly.

User manual:

Insert the plastic pellets into the plastic injection molding machine according to the manufacturer’s instructions.

Activate the screw cleaning process and wait until the process is completed.

Safety note:

Follow the manufacturer’s instructions for cleaning and maintaining the plastic injection molding machine.

Benefit:

Increase the life of the Screw: Support maintain and clean the screw, extending the life of the device.

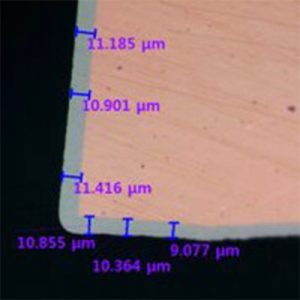

Reduced Wear: Prevents wear and minimizes damage caused by residue and plastic debris accumulating on the screw.

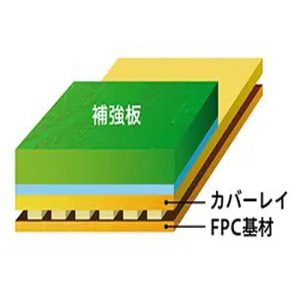

Application: Screw cleaning plastic pellets are widely used in the plastic injection molding industry, including the production of molded plastic products and other plastic applications.

Screw cleaning pellets are an important tool to maintain the performance and durability of plastic injection molding machines. They help remove impurities that can cause wear and tear and ensure stable operation of the device. Using plastic screw cleaning granules is an effective and time-saving way to maintain plastic injection molding machines.

Reviews

There are no reviews yet.