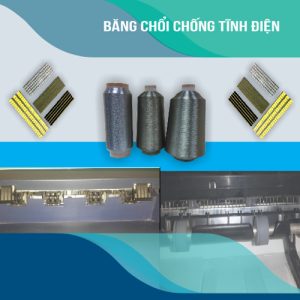

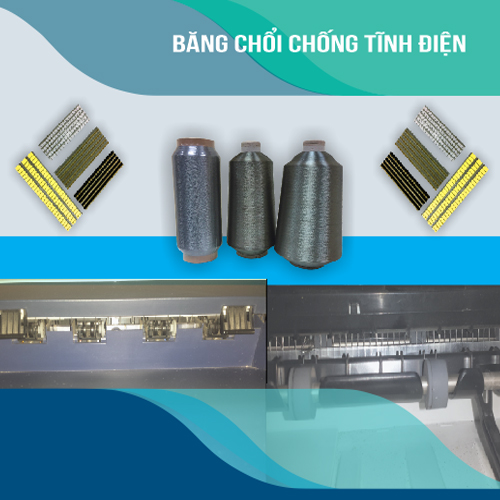

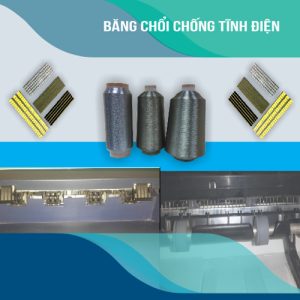

The movement of mechanical parts in machinery and equipment itself generates unwanted electrical particles, causing destruction or causing electrically charged components to greatly affect their usability of products. In office machines such as printers, fax machines, and ATM machines, the process of pulling paper and magnetic cards on the shafts generates electrical charges, causing the print quality to vibrate, deform the handwriting, and cause the machines to become electrically charged. causing the machine’s working processes to be affected incorrectly.

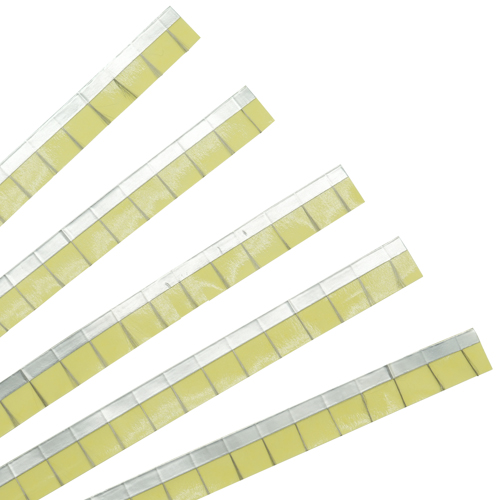

We have understood that problem and produced brush tapes made from adhesive and conductive adhesive tapes and special conductive brush, with the strengthening support of PET. film, has an adhesive surface that is easy to manipulate and attach to machinery positions and moving areas, capable of recovering generated charged particles and transmitting them to the ground pole and effectively neutralizing the charge.

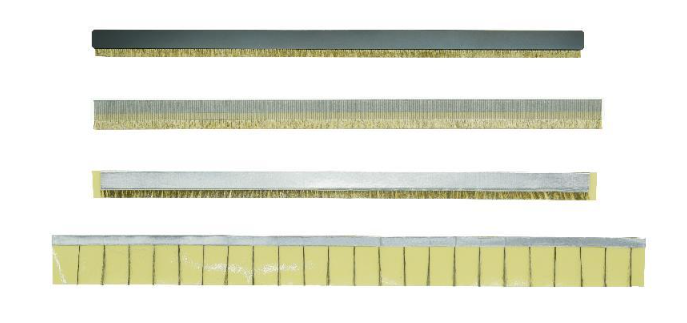

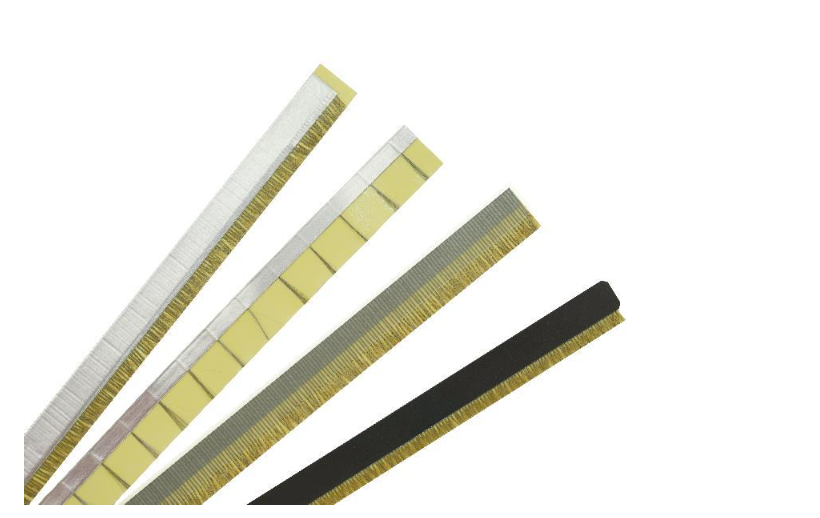

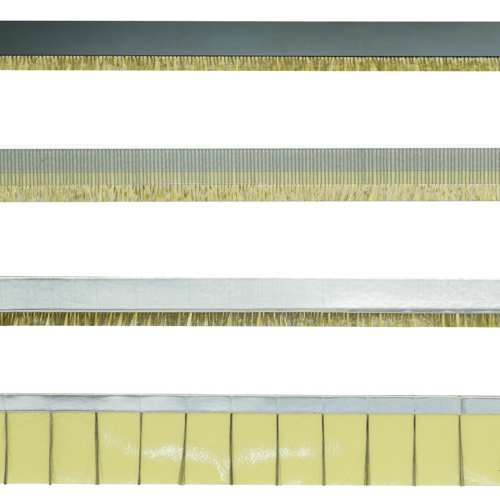

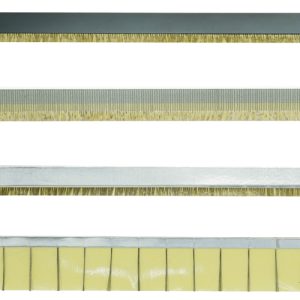

Structural basis of an antistatic brush:

Conductive tape: has the function of conducting ionized particles to the ground part of the device.

Double side tape: has the function of connecting to the device’s part surface

Antistatic brush: Made from many microscopic threads into a thread bundle that has the function of recovering ions automatically generated from the movement of chain guide machine components with the conductive tape to the ground contact part of the machine. device to neutralize electrical charges.

The hard plate is supported with PET to create stiffness for the tape, making it easy to manipulate and assemble into the machine, increasing the durability of the slide.

Reviews

There are no reviews yet.